Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

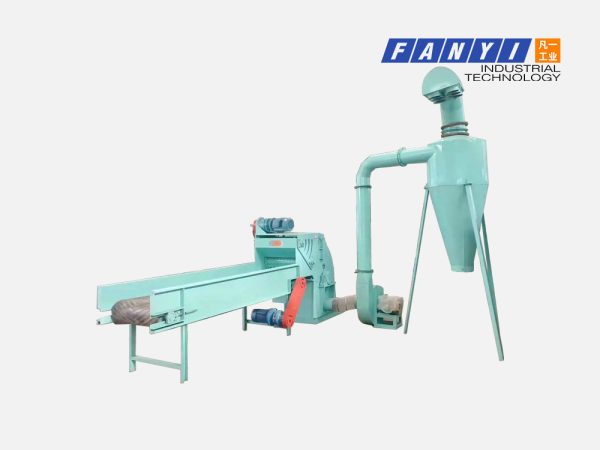

Industrial wood hammer mills are machines used to break down wood into smaller, more manageable pieces. They are essential in the wood processing industry as they make it possible to process wood waste into valuable products such as wood pellets, wood chips, and sawdust. Wood crushers work by using a combination of cutting, grinding, and chipping mechanisms to reduce wood logs, branches, and other wood waste into a uniform and consistent size suitable for further processing.

The raw materials typically used in wood hammer mills are wood logs, branches, roots, bark, and other wood waste products. These materials are first fed into the hopper of the wood crusher, where they are chopped and processed by a series of sharp blades or hammers. The blades or hammers rotate at high speeds, chopping the wood into smaller pieces until it is small enough to pass through a screen, which separates the final material from unwanted debris such as stones, metal, plastics, and other non-wood materials.

The Structure and working principle:

The dust removal equipment for the wood hammer mill is designed to remove sawdust and other small particles from the air, ensuring that the work environment is clean and that the operators are not exposed to dangerous dust particles. This dust removal system utilizes various components, including a forced feeding mechanism, a fan, and a shaking screen.

The forced feeding mechanism is designed to ensure that the wood chips are fed into the machine at a continuous and steady pace. This helps to prevent blockages and ensures that the machinery operates smoothly.

The fan is responsible for drawing air through the system and directing it toward the dust collector. This fan also helps to cool the machine, preventing it from overheating during operation.

The shaking screen is used to separate the sawdust and other small particles from the larger wood chips.

The screen is made up of a series of mesh screens that vibrate, causing the smaller particles to pass through the screen while retaining the larger wood chips.

The sawdust and other small particles are then collected in the dust collector, where they are captured and removed from the air.

The entire system is carefully designed to ensure that the sawdust and other small particles are removed from the work environment, improving the safety and health of the operators, and creating a cleaner work environment. The dust removal equipment for the industrial wood hammer mill is easy to use, and requires minimal maintenance, making it an efficient and reliable addition to any wood processing operation.

Technical Data:

| Model | HMD800 | HMD1000 | HMD1200 |

| Capacity | 1.5-2t/h | 2.5-3t/h | 3.5-4t/h |

| Main motor power | 45kw | 75kw | 90kw |

| Force-feeding conveyor power | 1.5kw | 2.2kw | 3kw |

| Force-feeding conveyor length | 2 meters | 2 meters | 2 meter |

| Force-feeding roller power | 1.5kw | 2.2kw | 3kw |

| Force-feeding roller quantity | 1 set | 1 set | 1 set |

| Air fan motor power | 7.5kw | 11kw | 18.5kw |

| Air fan quantity | 1 set | 1 set | 1 set |

| Cyclone quantity | 1 set | 1 set | 1 set |

| Cyclone diameter | 800mm | 1000mm | 1200mm |

| Air lock motor power | 1.1kw | 1.5kw | 2.2kw |

| Air lock quantity | 1 set | 1 set | 1 set |

| Bag-type dust collector | 1 set | 1 set | 1 set |

| Dust collect bags quantity | 10 pcs | 14 pcs | 20 pcs |

| Rotor diameter | 750mm | 950mm | 1150mm |

| Cutting blades quantity | 4 pcs | 4 pcs | 6 pcs |

| Cutting blades length | 230mm | 300mm | 350mm |

| Hammers quantity | 48 pcs | 64 pcs | 76 pcs |

| Equipped sieve hole diameter | 6mm or 8mm or 10mm | 6mm or 8mm or 10mm | 6mm or 8mm or 10mm |

| Finished sawdust size | 4-5mm or 5-8mm or 8-10mm | 4-5mm or 5-8mm or 8-10mm | 4-5mm or 5-8mm or 8-10mm |

| Electric panel | 1 set | 1 set | 1set |

wood hammer mill factory:

Industrial Wood hammer mill has several advantages:

1. High Efficiency: A wood crusher can process a large volume of wood quickly and efficiently, which can significantly reduce the amount of time and manpower required for the task.

2. Low Maintenance Cost: Wood chipper has a simple and robust design, which makes it easy to operate and maintain. It also helps in reducing maintenance costs.

3. Multi-functionality: A wood grinding machine can be used for grinding, chopping, and crushing different types of wood materials into different sizes as per the requirement, which makes it a versatile tool.

4. Power and Energy Saving: The wood sawdust-making machine is equipped with advanced technology that saves power and energy during operation, which makes it an economical option for businesses.

5. Environmental Friendly: The wood hammer mill is designed to operate with minimal environmental impact, which is essential for promoting sustainability and protecting the environment.

You must be logged in to post a review.

Reviews

There are no reviews yet.