Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

1. The driving shaft and driven shaft of high pressure briquetting machine are ensured to operate synchronously through open gear. Behind the driven bearing pedestal, there is hydraulic equipment.

2. The spiral feeder machine is driven by electromagnetic variable-speed motor through belt pulley and worm reducer to force the materials to be pressed into the main feeding mouth.

3. Due to the constant torque of the electromagnetic variable-speed motor, skillful operation technique is an important condition to ensure the normal work of the high pressure briquetting machine.

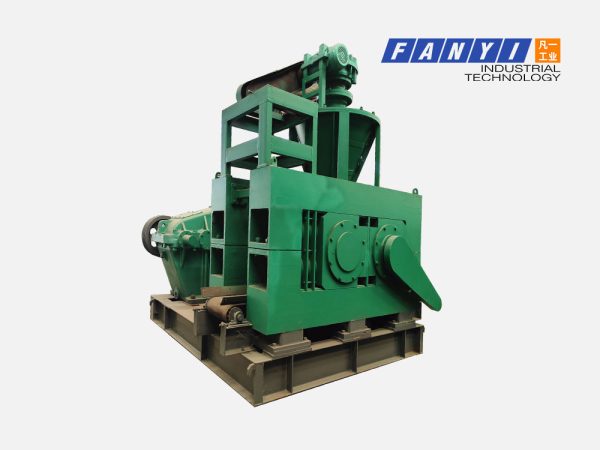

Force feeding briquette machine adopt the hydraulic force, briquetting twice for the final product, features in high pressure and high strength of briquette. It is widely used in metallurgical, chemical, and refractories industry, applicable to limestone powder, magnesium oxide powder, copper powder, chromium powder, lead, zinc scrap, bauxite, nonferrous metal powders, coal, charcoal powder, refractory materials, ceramic materials and other materials.

Stable Performance and Force Feeding Coal Briquetting Machine

Suitable raw material for briquetting

Iron powder materials

Color and black metallic mine powder

Coal powder or charcoal powder

Other kind of powder material

Available shape of the final product

Oval, egg, square, pillow, bread shape etc, the one install the original machine is oval shape, if you need the other shape, we can change the roller for you, expect the oval shape

Stable Performance and Force Feeding Coal Briquetting Machine

Working principle

This series of briquetting machine will pass the power on to the two pressure roller through the reduction gears. The two sides and roll rotation, in both the rotating roll,Natural materials to enter the ball roll mode, with the roll rotation, material pressure on a small become larger, When the material to the two rollers rotating line contact point, the pressure of materials has reached the peak. Tremendous pressure in the role of line, the materials become a finished product from the powder ball.

Note:

How to choose a suitable briquette machine:

1. What’s the raw material?

As different materials match different machines, So pls tell us what’s the raw material, is it limestone powder, coal powder or other metal powder.

2. The moisture of raw material

The moisture determines whether dryer is needed in the process.

3. The size of raw material

It should be crushed if the size is too big.

4. Capacity you need

Different capacity match different models of machine, what’s more, the smaller the capacity is, the simpler the process will be.

Technical Data

Constant briquette machine

| Model | RollerDia.r (mm) |

Roller Width (mm) |

Shaft Speed (r/min) |

Reducer Model | Pressure Form | Motor Power (kw) |

Capacity (t/h) |

| YQJ-290 | 290 | 200 | 18 | ZQ350 | Constant Wedge Pressure | 5.5 | 1-2 |

| YQJ-360 | 360 | 250 | 18 | ZQ400 | Constant wedge pressure | 7.5 | 2-4 |

| YQJ-400 | 400 | 250 | 18 | ZQ400 | Constant Wedge Pressure | 11 | 4-6 |

| YQJ-500 | 500 | 300 | 13 | ZQ500 | Constant Wedge Pressure | 18.5 | 6-10 |

| YQJ-650 | 650 | 336 | 13 | ZQ650 | Constant Wedge Pressure | 30 | 10-15 |

Force feeding briquette machine

| Model | Roller Size(mm) | Total Pressure (t) |

Main Power (kw) |

Pre-press Power (kw) |

Hydraulic Pump Power (kw) |

Capacity (t/h) |

|

| Dia. | Width | ||||||

| QYQ-476-1 | Φ476 | 196 | 95 | 45 | 15 | 1.5 | 1-3 |

| QYQ-476-2 | Φ476 | 210 | 95 | 55 | 15 | 1.5 | 2-4 |

| QYQ-520 | Φ520 | 196 | 95 | 55 | 15 | 1.5 | 3-5 |

| QYQ-650 | Φ650 | 196 | 100 | 75 | 18.5 | 1.5 | 4-6 |

| QYQ-672 | Φ672 | 275 | 100 | 75 | 22 | 2.2 | 6-10 |

| QYQ-750 | Φ750 | 196 | 120 | 110 | 22 | 2.2 | 5-8 |

| QYQ-850 | Φ850 | 196 | 120 | 132 | 22 | 2.2 | 6-10 |

Hydraulic high pressure briquette machine

| Model | Roller Dia. (mm) |

Roller Width (mm) |

Motor Power (kw) |

Shaft Speed (r/min) |

Reducer Model | Capacity

(t/h) |

Roller Material |

| YYQ-476 | 476 | 210 | 22/1.5 | 15 | ZQ500 | 3-6 | 65Mn |

| YYQ -476 | 476 | 260 | 30/1.5 | 15 | ZQ650 | 4-8 | 9Cr2M0 |

| YYQ -500 | 500 | 300 | 30/1.5 | 15 | ZQ650 | 5-9 | 65Mn/9Cr2M0 |

| YYQ -650 | 650 | 336 | 45/1.5 | 15 | ZQ750 | 8-15 | 65Mn |

| YYQ -672 | 672 | 275 | 75/1.5 | 13 | ZQ1000 | 8-15 | 9Cr2Mo |

| YYQ -750 | 750 | 400 | 55/1.5 | 13 | ZQ850 | 15-20 | 65Mn/9Cr2Mo |

| YYQ -850 | 850 | 500 | 75/1.5 | 10 | ZQ850 | 20-30 | 65Mn/9Cr2M0 |

| YYQ-1000 | 1000 | 650 | 110/1.5 | 10 | ZQ1000 | 30-50 | 65Mn/9Cr2M0 |

You must be logged in to post a review.

Reviews

There are no reviews yet.