Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Applications: Rod mills are widely used in refractory, chemical, metallurgy, glass and other industries. Especially suitable for grinding operations that require high uniformity of the finished product after grinding.

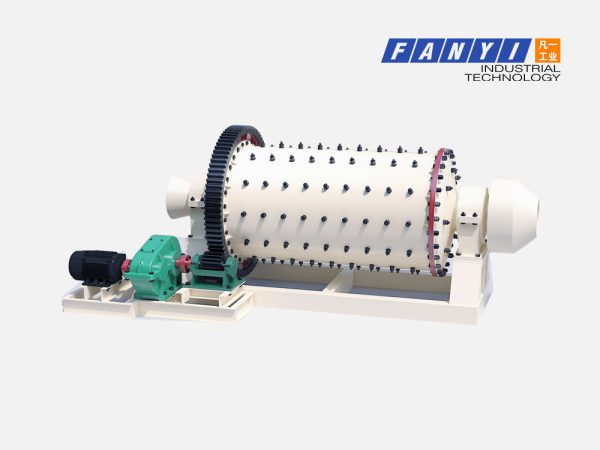

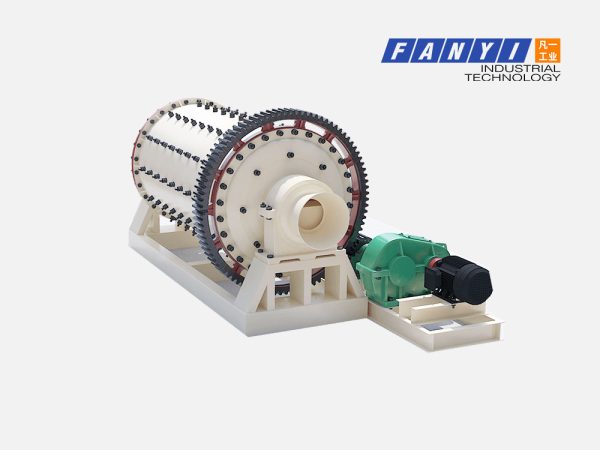

Rod mill is a kind of ore grinding mill with steel rod as grinding medium to grind materials. Rod mill design for the fine and coarse grinding of various hardness of ore materials with wet process. Compared with ball mills and vertical roller mills, rod mills process materials more delicately, and can be used in material grinding processes for fine processing needs.

As experienced rod mill manufacturers and suppliers developed the new rod mill adopts the latest production technology. Combined with the grinding materials in the actual production, the rod mill is equipped with the grinding medium steel rod with high quality steel materials. The new mining rod mill operation uses a linear contact method instead of the traditional surface contact grinding method to make the rod mill’s output more uniform and higher output. The rod mill crusher can be widely used in mineral processing, building materials, chemical industry, refractory and other industries, as well as in the grinding of materials with high requirements for the uniformity of the finished products after grinding.

There are three main types of rod mills for sale according to different ways of discharging.

Overflow rod mill

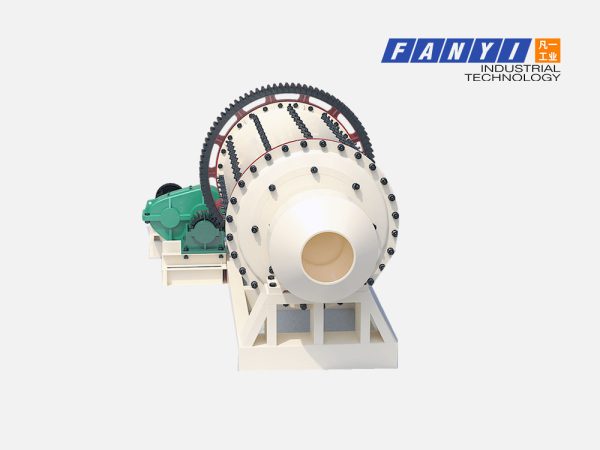

The center of the discharge end of the overflow rod mill is provided with an overflow port with a large aperture, and the discharge port is provided with a conical cover, so as to avoid slurry splashing and steel rod sliding out of the mill barrel. Overflow rod mill is the most common mining rod mill model. The product particle size is finer than the other two rod mills, generally used to grind the crushed products, and then provide it to the ball mill for further grinding.

End peripheral ore discharge rod mill

The discharge end of this mining rod mill is located at the end of the barrel. The finished products have coarse particle size and can be used in dry, wet and wetting grinding operations.

Central peripheral ore discharge rod mill

The discharge end of this mining rod mill is located in the middle of the barrel. The product particle size is coarser than the above two types of rod mills and can be used for dry and wet grinding. The material enters the barrel from both ends of the rod mill, the grinding process is short, and it is discharged quickly. Moreover, the rod mill crusher has a high gradient and is mainly used in the aggregate and sandstone industries.

The rod mill working principle and structure is roughly the same as that of the overflow ball mill, but there are also differences.

| Specification(mm) | Capacity(t/h) | Output Size(mm) | Rotate Speed(r/min) | Motor Power(kW) | Weight(t) |

|---|---|---|---|---|---|

| φ900×1800 | 0.62-3.2 | 0.833-0.147 | 36-38 | 18.5 | 5.9 |

| φ900×2400 | 0.81-4.3 | 0.833-0.147 | 36 | 22 | 6.7 |

| φ1200×2400 | 1.1-4.9 | 0.833-0.147 | 36 | 30 | 13.9 |

| φ1500×3000 | 2.4-7.5 | 0.833-0.147 | 29.7 | 75 | 19.8 |

| φ1830×3000 | 4.8-11.6 | 0.833-0.147 | 25.4 | 130 | 34.9 |

| φ2100×3000 | 14-35 | 0.833-0.147 | 23.7 | 155 | 46.5 |

| φ2100×3600 | 19-43 | 0.833-0.147 | 23.7 | 180 | 48.7 |

| φ2400×3000 | 25-65 | 0.833-0.147 | 21 | 245 | 59.7 |

| φ2700×3600 | 32-86 | 0.833-0.147 | 20.7 | 380 | 92.5 |

| φ2700×4000 | 32-92 | 0.833-0.147 | 20.7 | 400 | 95 |

| φ3200×4500 | 64-180 | 0.833-0.147 | 18 | 630 | 149 |

|

|

|

|

|

| cobblestone | Limestone | Dolomite | Quartz | Weather fossil |

|

|

|

|

|

| Granite | Coal gangue | Iron ore | Copper ore | Lead-zinc mine |

You must be logged in to post a review.

Reviews

There are no reviews yet.