Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

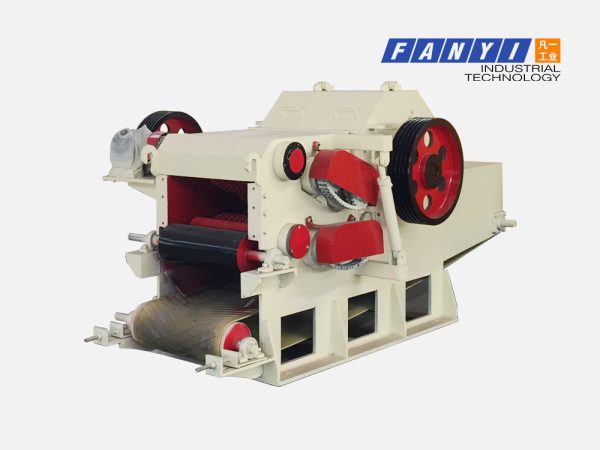

Drum chipper is heavy-duty equipment for producing wood chips. It is widely used in the material preparation section of wood chip mills, particleboard, fiberboard, paper mills, biomass fuel plants, etc.

The raw materials processed by the drum chipper are mainly logs, waste wood, wooden pallets, building templates, nailed boards, wood cutting residues (branches, twigs, etc.), and wood raw material processing residues (slabs, slats, round wood cores, waste veneers, etc.), which can also be used to cut non-wood materials (such as sugarcane, reed, bamboo, etc.).

Drum chipper is heavy-duty equipment for producing wood chips. It is widely used in the material preparation section of wood chip mills, particleboard, fiberboard, paper mills, biomass fuel plants, etc.

The raw materials processed by the drum chipper are mainly logs, waste wood, wooden pallets, building templates, nailed boards, wood cutting residues (branches, twigs, etc.), and wood raw material processing residues (slabs, slats, round wood cores, waste veneers, etc.), which can also be used to cut non-wood materials (such as sugarcane, reed, bamboo, etc.).

1. Drum chipper machine technical data

| Model | BX216 | BX218A | BX218B | BX2110 | BX2113 |

| Capacity | 5-8t/h | 8-12t/h | 10-15t/h | 15-20t/h | 20-30t/h |

| Main motor | 55kw | 110kw | 110kw | 160kw | 200kw |

| Inlet conveyor | 6m | 6m | 6m | 6m | 6m |

| Inlet conveyor motor | 4kw | 4kw | 4kw | 11kw | 11kw |

| Feeding roller | 4 units | 4 units | 4 units | 6 units | 6 units |

| Feeding roller power | 3kw | 4kw | 4kw | 11kw | 11kw |

| Cutting drum diameter | 600mm | 800mm | 800mm | 1000mm | 1300mm |

| Cutting drum speed | 650rpm | 590rpm | 590rpm | 500rpm | 500rpm |

| Inlet chute size | 500x230mm | 600x300mm | 800x400mm | 1000x500mm | 1300x500mm |

| Rotating blade | 3pcs | 3pcs | 3pcs | 2pcs | 2pcs |

| Bottom blade | 1pc | 1pc | 1pc | 1pc | 1pc |

| Feeding speed | 0.63m/s | 0.63m/s | 0.63m/s | 0.63m/s | 0.63m/s |

| Max intake wood Φ | <20cm | <28cm | <35cm | <40cm | <40cm |

| Wood chip size | 20-35mm | 20-35mm | 20-35mm | 20-35mm | 20-35mm |

| Outlet conveyor | 10m | 10m | 10m | 10m | 10m |

| Outlet conveyor motor | 3kw | 4kw | 4kw | 5.5kw | 5.5kw |

| Hydraulic pump motor | 1.5kw | 2.2kw | 2.2kw | 3kw | 4kw |

| Dimension | 1980x1950x1250 | 2300x2150x1500 | 2450x2200x1550 | 3670x2448x2050 | 3850x2550x2100 |

| Weight | 4.1 ton | 7.2 ton | 7.8 ton | 12 ton | 14.5 ton |

| Install size | 20x3x3.5m | 20x4x3.5m | 20x4x3.5m | 25x5x4m | 25x5x4m |

|

|

|

| The crushing chamber of the drum wood chipper is covered for safety and the cover lifts easily by hydraulics. This makes maintenance and changing blades easy and convenient. | The blade material is H13. It is harder and resistant to wearing. It can cut hardwood and has a longer service life before needing sharpening. For best results, the blade should be sharpened after every 1000 hours of use. | The wood chipper’s feed roller is made of 45# Mn steel. This steel alloy has strong abrasion and a precise bite force, helping to reduce the chance of damage to the chipper. |

|

|

|

| The body material is strong carbon steel – Q235. This allows it to run steadily without ground foundation. | The feeding chain conveyor feeds the raw material evenly, regardless of size or shape, preventing dangerous blockages. | The screen mesh size can be customized for different sizes to produce end products to specific requirements. |

2. Drum wood chipper introduction

BX series drum wood chipper is designed to chipping wood logs, tree branches, wasted wood, wood residues, woodcuts, bamboo, into 2-3cm size wood chips or bamboo chips, use this chipper also can shredding EFB to 10-50mm length EFB fiber.

This machine is usually applied by chips making industry, wood pellets-making industry, and paper-making industry. Drum wood chipper is made up of a feeding conveyor, feeding roller, knife roller, blades, screen, motor, frame, hydraulic system, and discharge conveyor.

1.The feeding conveyor help the feeding of wood easier, can manually load or use timber grab/ loader machine put the wood logs, wasted wood, bamboo, tree branches on the feeding conveyor, the conveyor is installed horizontally on the ground, it can send wood to feeding inlet of the wood chipper.

2.The feeding rollers are installed at the feeding inlet, it has two layers, the down layer is stable while the upper layer is movable with the hydraulic system thus adjusting the feeding ability. When wood comes from the conveyor, the teeth on the rollers will bite the wood with the rotating of feeding rollers the wood will feed into the drum chipper, then the wood will go to the knife roller.

3.The knife roller is in the center of the wood chipper, it is rotating together with the main motor, on the knife roller there are rotary blades, and on the frame of the wood chipper there is one bottom blade, when the wood comes to knife rollers, with the rotating of rotary blades, when the rotary blade come to stable blade the wood will be cut into chips.

4.The hydraulic oil pump is equipped with the feeding rollers, thus it can raise up the feeding chute upper plate a bit to let bigger diameter wood intake wood chipper easier, and then the chute upper plate falls down slowly to protect the feeding rollers.

5.The wood chips will fall down to the screen, and from the holes, on-screen the chips go to the discharge conveyor and send away.

Our drum wood chipper is designed with a base frame, so no need to make a foundation during installation

The drum wood chipper is suitable for different kinds of raw material like wood logs, woodcuts, tree branches, wasted wood, wood residues., wood material, bamboo, EFB, and building templates

The drum wood chipper is equipped with an electric panel, from this panel can control the start and stop of the main motor, feeding roller motor, feeding conveyor motor, discharge conveyor motor, and hydraulic system motor

We have different model drum wood chipper for different user requirement, each model chipper the maximum wood diameter it can handle is decided when the client choose a drum wood chipper should pay attention to your maximum wood diameter and then choose a suitable model

Our service

1. Guarantee/warranty period: 12 months (except wearing parts on pellet mill). During the guarantee period, if the machine breaks down without any artificial factors or buyer operation mistakes, Zhengzhou Fanda Machinery Co., Ltd will provide replacement parts at its own cost and help the buyer to repair the machine until the machine can normal running. After the guarantee period, we provide replacement parts at the buyer’s cost.

2 After-sales service: We provide an operation manual for our machine in the English version, we have a lifetime after-sales service for our machine. During buyers use our machine if there is any service required, they can get our online service easily and rapidly.

3 Shipping the above-listed machines takes one 20 feet container.

4 Deliver period of the above machines is 15-20 working days after received your down payment.

5 We provide different colors for the painting of the machines, we can paint the machine as your requirement on the color.

In order to serve you better, please try to provide the below information:

1) What is the material to be crushed? If timber, what kind of wood?

2) Hardness?

3) Moisture content?

4) Maximum diameter of the material to be crushed?

5) Maximum length of the material to be crushed?

6) Required production capacity?

7) Required chips size?

8) What will wood chips be used for ? ( making wood pellets? For biomass power plant? Etc)

9) Working location of the machine?

10) Other special requirement which you think necessary to let me know?

Then we will recommend suitable model based on your actual needs.

You must be logged in to post a review.

Reviews

There are no reviews yet.