Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

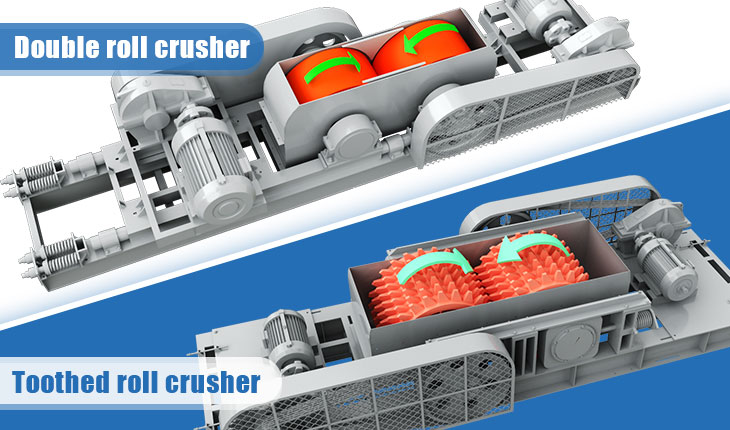

Depending on the number of rolls, roll crushers are classified into single-roller type and double-roller type, while according to the smoothness of the rollers, they are classified into single-roller type or hobbing type.

Double-toothed roller crushers are commonly used in mineral processing plants. The crushing ratio is 3~15, and the particle size must not exceed 25mm.

Motor power: 75kw

Feed particle size: ≤40mm

Production capacity: 5-110t/h

Uses: Crushing medium and high-hardness materials in metallurgy, construction, refractory materials and other industries.

Roller Crusher, Double Roller Crusher, Toothed Roll Crusher, Double toothed roll crusher

Double toothed roll crusher is essential equipment in small stone factories and it is a commonly used type of roller crusher. Because of its simple structure, easy maintenance, and low price, it is popular to aggregate and coal ore suppliers.

According to the number of rollers, the roll crushers can be divided into three types: single roll crusher, double-roll crusher, and multi-roll crusher. And the most common one is double-roll crusher.

According to the surface of rolls, it can be divided into smooth roll crusher and toothed roll crusher. (The following roll crusher refers to “smooth roll crusher”.)

Types of roll crushers

Double toothed roll crusher is suitable for crushing various types of ores, used as secondary or tertiary crushing machinery. It is widely used in construction, metallurgy, building materials, water conservancy, electricity, refractory, and other industrial sectors.

Double toothed roller crusher is generally used for crushing medium-hard rocks with compressive strength of less than 200 Mpa, such as limestone, phosphate, basalt, granite, river pebbles, iron ore, gold ore, copper ore, lead-zinc ore, nickel ore, asphalt, bricks, cement, and other materials.

Double toothed roller crusher is a new type of equipment recommended by major coal plants for crushing raw coal, coke, lignite, and activated carbon. It crushes the coal by squeezing the double toothed rollers and easily removes the materials adhering to the rollers.

The roller crusher has dual functions of pre-screening and crushing. Small and medium-sized materials in the coal mine are directly leaked from the gap between the toothed rollers to avoid reprocessing. The phenomenon of over-crushing is improved.

The toothed roller crusher is very useful for crushing clay, cohesive materials, or rocks mixed with soil with water content up to 30%, such as kaolin, bentonite, montmorillonite, etc.

Because equipped with a scraper and adjustable discharge size, it can keep the groove and working surface clean. For wet and viscous materials, it can easily complete the crushing operation without sticking or clogging.

The double roller crusher is equipped with a discharge regulating device. The crushing gear is operated by a hydraulic system, which is used to adjust the space between tooth rollers, more convenient and fast operation.

According to the actual production requirements, the users can adjust the size of the discharge by adjusting the top bolt of the wedge-shaped device. The particle size of the crushed product can reach 2-10 mm, to meet the need of different users.

A double toothed roll crusher with less volume is composed of two toothed rollers, which are installed in parallel and rotated in opposite directions.

The two-toothed rollers adopt non-meshing and non-constant speed operation to strengthen the degree of occlusion, which ideally prevents the material from slipping thus improving the crushing efficiency.

Generally speaking, materials are crushed in three stages in a double toothed roller crusher.

Toothed roll crusher has good applicability and plays an important role in open-pit mining, especially in open-pit coal production. Four reasons for open-pit ore crushing:

The teeth of the crusher are composed of large and small teeth at intervals, which can effectively improve the meshing ability of the toothed rollers while ensuring the ideal particle size. Strong meshing capacity can improve the equipment processing capacity, reduce the tooth roller wear, and prolong the tooth plate service life.

The connection between the tooth plate and tooth roller seat adopts a screw fastening block. It not only guarantees connection strength, but also has good interchangeability and replaceability.

The motor is equipped with an electric heating system, and the hydraulic coupling and reducer use low-temperature synthetic oil, which ensures the transmission system’s smooth operation even at a low temperature of -30°C.

The tooth plate adopts medium carbon bainite wear-resistant cast steel. The wear resistance of this material is about 40% higher than that of the surfacing wear-resistant layer of 40Cr steel. In addition, the entire tooth roller structure, including the toothed plate, toothed roller seat, and threaded fastening block makes the strength and hardness of each component more balanced and reasonable.

Technical Data of double toothed roll crusher:

| Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

| Roller diameter(mm) | Ф400 | Ф600 | Ф700 | Ф800 | Ф1000 | Ф1200 | Ф1500 |

| Roller width(mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

| Input Size(mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

| Discharging Gate(mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 | 2-10 |

| Processing capacity(t/h) | 3-10 | 5-20 | 10-30 | 15-40 | 20-50 | 25-70 | 30-110 |

| Power Models | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |

| Motor power(kw) | 5.5×2 | 15×2 | 30×2 | 45×2 | 55×2 | 75×2 | 110×2 |

Note: Capacity May Vary with Different Materials and Feed Sizes.

You must be logged in to post a review.

Reviews

There are no reviews yet.