Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Round Gold Crushing Wet Pan Mill is also called wet grinding machine and gold grinding mill, it’s a modernized grinding machine, commonly used in the small and medium size concentrate factory. It is widely applied to the grinding and benefication of all kinds of metal minerals, non-metal minerals, rare metal and other materials. Such as gold, silver, lead, zinc, molybdenum, iron, copper, antimony, tungsten, tin and so on.

Wet pan mill is also called wet grinding machine and gold grinding mill, it’s a modernized grinding machine, commonly used in the small and medium size concentrate factory. It is widely applied to the grinding and benefication of all kinds of metal minerals, non-metal minerals, rare metal and other materials. Such as gold, silver, lead, zinc, molybdenum, iron, copper, antimony, tungsten, tin and so on.

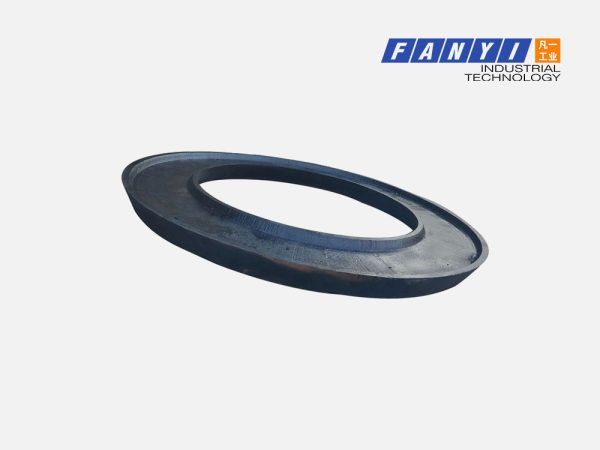

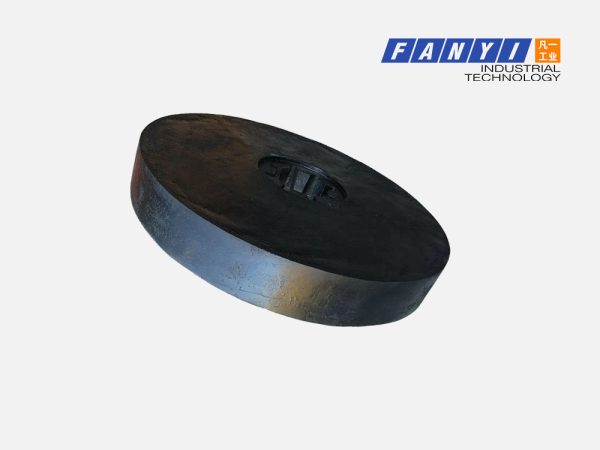

Round Gold Crushing Wet Pan Mill mainly include power plant, frame, birdbath, grinding wheel, pan and other parts. Wet pan mill grinds ores by wheel driving force. Firstly, the power is transferred from the motor to the reducer, then to the horizontal shaft, and finally to the grinding wheel; the wheels then rotate anticlockwise. The wheels can revolve around the vertical shaft of the pan mill, and at the same time, it can revolve on its own axis, while the grinding base will remain still. The ores are pressed, rubbed and grind repeatedly.

1. The ore and water are evenly mixed, which makes the pulp density and other indexes stable.

2. After the grinding process, the monomers are taken to the upper surface of the pulp and discharged through the overflow outlet of the water basin. Meanwhile, the coarse ores sink to the bottom of grinding base, being grinded continuously till they reach the required fineness.

3. The screening mesh set up at the overflow outlet of the water basin classifies the ore fineness strictly to avoid the over-grinding and uneven fineness, which helps create better condition for next working process.

1. Professionally-designed, thus its technical data is reasonable.

2. Short grinding and mixing cycle, high efficiency.

3. Low noise and low consumption. The materials can be grinded and mixed uniformly.

4. Compact structure, easy to operate and maintenance.

| Model | Specification | Input size(mm) | Rotate Speed (r/min) | Powder(kw) | Weight(t) |

| 1600A | 1600×400×200×500±20mm | 20-22 | 25KW | 14.5 | |

| 1500A | 1500×350×200×460±20mm | 20-22 | 22KW | 13.5 | |

| 1400A | 1400×250×150×350±20mm | 16-18 | 18.5kw | 8.5 | |

| 1400B | 1400×250×150×350±20mm | 21-23 | 18.5kw | 8.5 | |

| 1350A | 1350×250×150×350±20mm | 16-18 | 18.5kw | 8 | |

| 1350B | 1350×250×150×350±20mm | <25mm | 21-23 | 18.5kw | 8 |

| 1300A | 1300×250×150×350±20mm | 16-18 | 15kw | 7.5 | |

| 1300B | 1300×250×150×350±20mm | 21-23 | 15kw | 7.5 | |

| 1200A | 1200×200×80×250±20mm | 17-19 | 7.5kw | 5.5 | |

| 1200B | 1200×200×80×250±20mm | 23-25 | 7.5kw | 5.5 |

3. There is a theory that if the weights of solid particles are different, the sedimentations will be different, and the mixed ore can be classified by screw classifier.

3) The classified ore gets into magnetic separator. Since the specific magnetization coefficients of ores are different, the magnetic

substance of mixed ore is separated from others with magnetic and mechanical force.

4) The beneficiation Equipments flow produced by our company can provide you with all-around technical support. According to

different customers and different mine, my company design different beneficiation complete sets of equipments for you.

You must be logged in to post a review.

Reviews

There are no reviews yet.