Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

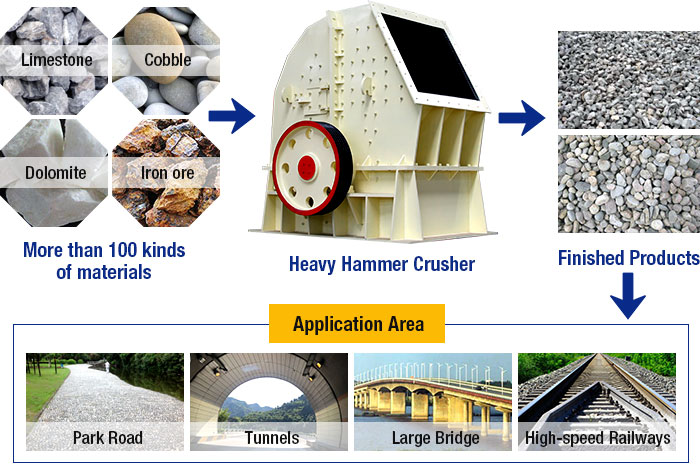

The hammer mill crusher is a type of ore crushing equipment. It can be used to crush medium-hard brittle materials with low water content, such as limestone, gypsum, slag, coke, coal, etc. It is widely used in cement manufacturing, chemical, electric power, metallurgy, and other industries.

CAPACITY: 15-310t/h

MAX FEEDING SIZE: 80mm-200mm

RAW MATERIALS: Limestone, marlstone, sand stone, gypsum, coal, etc

APPLICATION: Chemical industry, construction, metallurgy, mining, coal beneficiation, sand making and fire resistant material industry.

Hammer crusher is also called hammer mill, or hammer mill crusher. It is a crusher that uses a series of rotating hammers to crush materials (600-1, 800 mm) into smaller pieces (below 25 or 25 mm).

The hammer crusher is very suitable for medium and fine crushing of medium-hard and brittle materials. It is known for providing greater crushing ratios in a variety of materials for the aggregate and industrial markets.

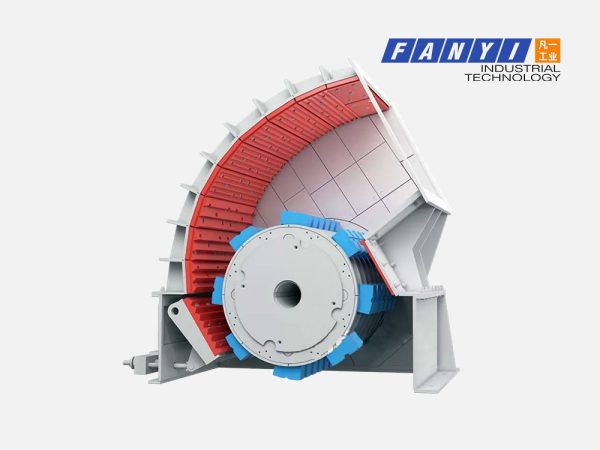

PCZ Heavy Hammer Crusher combines the advantages of the jaw crusher, hammer crusher, and impact crusher. It has a larger input size ((≤1, 000 mm) and greater capacity (≤3, 000 t/h).

Uper fine crushing: Reasonable multiple crushing chamber combination, new convenient double adjustment structure, the output size being smaller than 3mm can reach 85%, finished particle size is fine and uniform.

Easy maintenance: Convenient inspection and maintenance device, which make hammer adjustment and screen plate become easier.

Super long life: Wear-out part adopts new excellent multielement high chromium alloy which ensure abrasive resistance and shock resistance of the liner plate.

High efficient Energy Consumption: This series crusher possesses stable operation, low dust, low power consumption.

Large crushing ratio: Secondary crushing and tertiary crushing can be integrated as primary crushing, crushing ratio reaches 25-30.

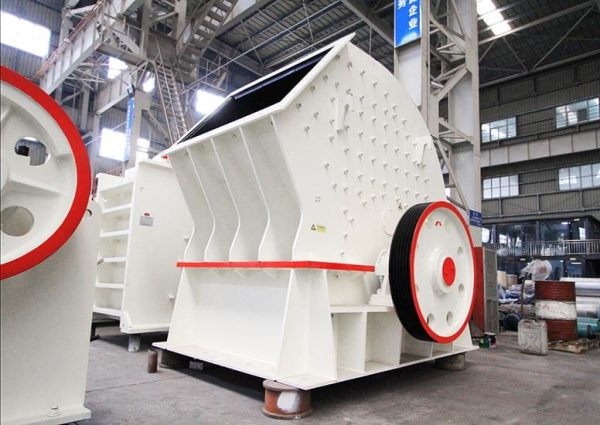

The hammer crusher has a simple and compact structure designed for superior operation and a long lifespan. It is easy to operate and maintain and has high wear resistance.

A hammer mill crusher is mainly composed of the frame, rotor, hammer head, main shaft, and other components.

The inner wall of the hammer mill is inlaid with wear-resistant steel lining plates. The impact plate is replaceable when worn.

Bearing supports are installed on the left and right-side walls for placing carbon steel welded bearings and supporting the rotor. The base of the frame is directly placed on the concrete foundation, with anchor bolts.

The left and right-side walls and the rear cover are welded with steel plates. To prevent dust leakage, a shaft sealing device is installed where the frame contacts the shaft.

The rotor is the main working part of the crusher, which consists of the rotor shaft and hammer head.

The motor drives the rotor directly through the elastic coupling. Then the materials are crushed due to the impact of the hammer on the crushing plate caused by the rotor rotation.

By adjusting the rotor speed, you can change the output size.

The hammer head, also known as the crusher hammer, is the main wearing part of the hammer crusher.

It is fixed on the rotor and crushes the material by impacting it. After crushing, the qualified materials are discharged from the grate bar.

The weight and material of the hammer head affect the capacity. Therefore, the hammer weight should be moderate (no more than 80 kg), and a good material should be selected.

The choice of the hammer head

| Types of hammer head | Features | Disadvantages |

| High manganese steel hammer head | Good toughness and wear resistance, low price, and wide application. | If the impact force is insufficient or the contact stress is small, its wear resistance cannot be exerted. |

| Low alloy steel hammer head | Less wear and tear, and longer service life than high manganese steel. | Complicated technology |

| High-chromium iron hammer head + high manganese steel or carbon steel hammer handle | Good wear resistance of hammer head and high toughness of hammer handle. | Complicated technology |

We use a third type of hammer, a high chromium iron hammer. This hammer head is made of chromium alloy containing 20-27% chromium, which is cast by new technology. Therefore, it has a low failure rate and a long service life.

Check the hammer regularly. Once worn enough, turn it over and use it on the other side. The worn hammer can be welded with a wear-resistant electrode to restore it. The weight of the replacement hammer head should be as equal as possible, and the deviation should be less than ±0.1kg.

The main shaft is part of the hammer mill supporting the rotor.

The mass of the rotor and hammer head, as well as the impact force and torque generated during rotation, are borne by the main shaft.

Therefore, the main shaft needs to have high strength and toughness, and adopted the high manganese steel forgings.

In addition, has also designed a dust seal and overload protection devices to ensure the environmental protection and reliability of the crushing process.

PCZ heavy hammer crusher is suitable for crushing limestone, marlstone, sand stone, gypsum, coal, etc, of which the crushing compressive strength does not exceed 200MPa. Meanwhile, it is also the supporting equipment for sand stone production line, ore beneficiation equipment, aerated concrete equipment. PCZ heavy hammer crusher possesses large crushing cavity and input opening, be suitable for large ore to be in smoothly.

Technical Data of PCZ heavy hammer crusher:

| Model | Rotor diameter×length (mm) | Feed Opening Length×width(mm) | Feeding Size (mm) | Processing Capacity(t/h) | Power (kw) | Dimensions L×W×H (mm) |

| PCZ1308 | Φ1330×790 | 870×780 | ≤380 | 60-160 | 132 | 2880×2130×2390 |

| PCZ1410 | Φ1400×1000 | 1060×740 | ≤450 | 80-210 | 2×90(160) | 2830×2100×2485 |

| PCZ1610 | Φ1600×1000 | 1090×930 | ≤480 | 100-230 | 2×132 | 3370×2415×2750 |

| PCZ1612 | Φ1600×1200 | 1340×1140 | ≤500 | 120-350 | 2×160 | 3370×2613×2750 |

| PCZ1615 | Φ1600×1500 | 1570×1140 | ≤550 | 200-550 | 2×200 | 3370×2925×2750 |

| PCZ1716 | Φ1700×1600 | 1420×1200 | ≤600 | 400-850 | 2×250 | 3520×3000×3210 |

| PCZ1720 | Φ1700×2000 | 2030×1200 | ≤650 | 500-1000 | 2×400 | 3670×3390×3330 |

| PCZ1920 | Φ1900×2000 | 1980×1210 | ≤750 | 800-1500 | 2×500 | 4490×3910×3600 |

| PCZ2225 | Φ2200×2500 | 2530×1610 | ≤1000 | 1500-3000 | 1250 | 4890×5010×4560 |

Note: Capacity May Vary with Different Materials and Feed Sizes.

You must be logged in to post a review.

Reviews

There are no reviews yet.