Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Before we go too far in-depth about how drum chippers work, let’s address the most pressing question – what exactly are drum chippers?

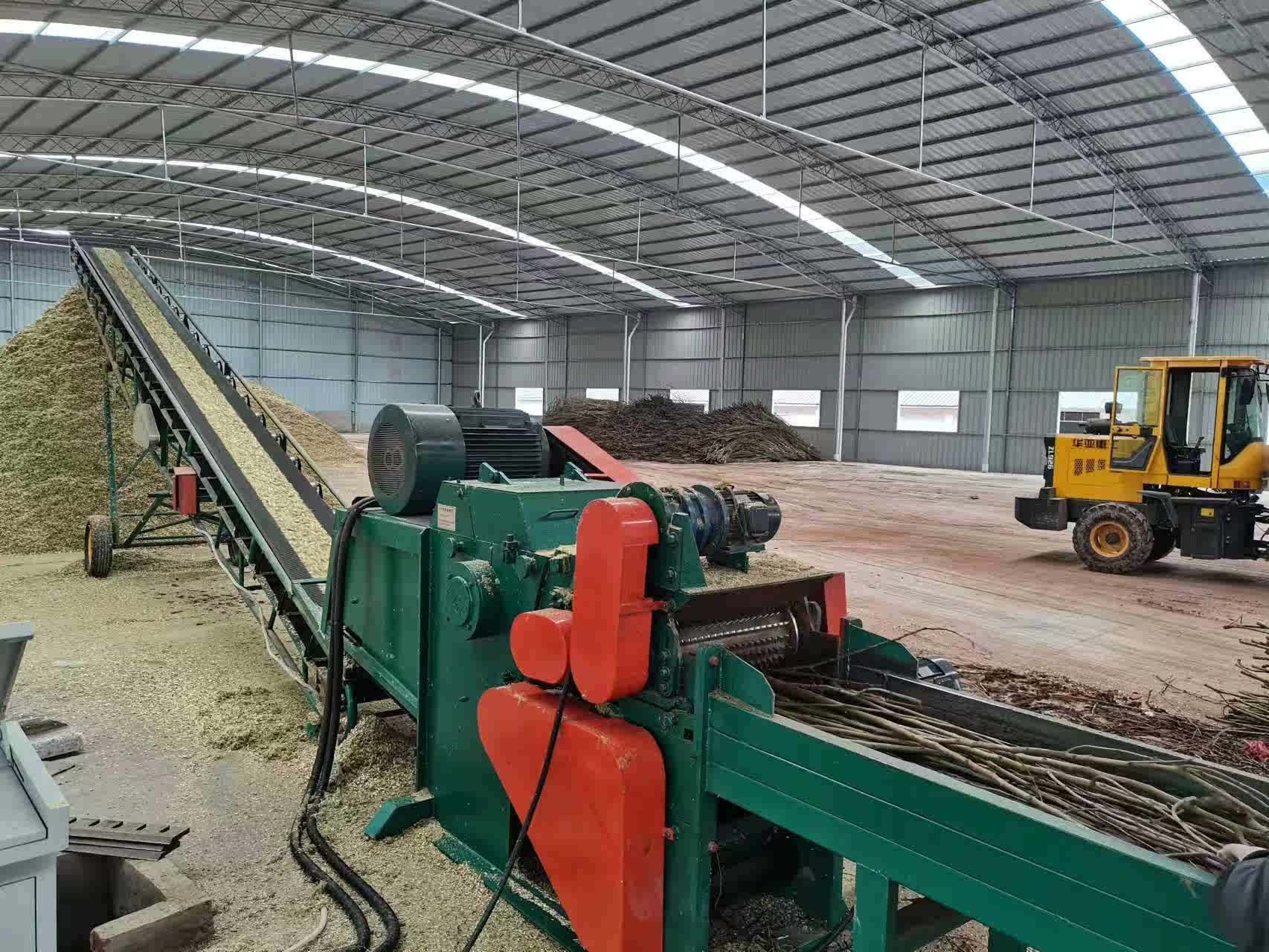

Drum chippers are specific types of wood chippers used to reduce wood (usually large tree limbs, branches, or trunks) into smaller wood chips. These are often portable, with the ability to mount them on wheels and frames that can then be towed behind tractors, vans, or trucks.

These tools are used commercially in wood pellet plants. Here, they are used to turn large bits of wood into usable chips that can then be processed even further into things like particle boards.

Drum chippers consist of a base, feeding rollers, knife rollers, a belt conveyor, and a simple hydraulic system. Generally, the main body is welded into a high-strength steel plate, with a set of two to four knives installed on each roller.

In addition to drum chippers, you can buy other types of wood chippers, too, including disk chippers and high torque rollers. Most drum chippers are electric drum chippers that are powered by a PTO, but there are some gas-powered chippers out there as well.

Now that you know exactly what a drum chipper is, here’s how to use one.

Wood chippers contain a variety of parts, including a collar, hopper, a chipper, and a collection bin (though this last item can be optional).

Drum chippers have large, motor-operated drums. These drums draw in material, then cut or shred it before directing it out a chute. These machines work quickly, making them ideal for commercial operations, but they can be quite loud.

They also require careful operation – the operator has to load equipment thoughtfully in order to avoid jams and blockages.

You may hear drum chippers referred to as chipper drums – don’t get confused! The two are one and the same.

Drum chippers are different from other types of wood chippers in how they operate. These, again, consist of large steel drums powered by motors. The drum tends to be mounted parallel to the hopper, spinning toward the chute as it cuts the material into chips. The chips are then propelled out of the discharge chute.

The diameter of wood that a chipper drum can handle varies based on the size of the machine. Most can handle wood material that is anywhere between nine and 24 inches in diameter.

In conventional chipper drums, the drum will be used as the feeding mechanism, both drawing the material through and chipping it. Also known as chuck and duck chippers, these chipper drums can be somewhat risky to use. The material is dropped so quickly into the drum that it is easy for them to kick back and injure the operator.

For the most part, hydraulically-fed drum chippers have now replaced most conventionally fed machines. These use hydraulic wheels to regulate the rate of feed, so it isn’t going in and out as quickly.

As mentioned earlier, there are several main types of wood chippers you can buy – drum chippers, disc chippers, and high torque rollers.

Drum and disc chippers tend to be the most common types of wood chippers by far. Both types have been in use for many years and have their own plusses and minuses.

We already told you all about how drum chippers work – here’s a quick overview of how disc chippers operate.

Disc chippers work a bit like drum chippers. The technology is old, dating back to 1922. Reversible hydraulically-powered wheels draw material from the hopper back toward the disk, which is mounted perpendicular to the material. The disk spins and the knives of the wood chipper cut the material up into chips.

These are then discarded from the chute by flanges that are positioned on the drum.

Disc chippers can usually handle material diameter that is 6 to 19 inches, though there are industrial-grade chippers with discs that can handle material up to 160 inches in diameter and require up to 5,000 horsepower to operate! These kinds of wood chippers are often used in industrial settings to produce things like particleboard.

Neither a drum chipper nor a disc chipper is better than the other – it all depends on your goals and priorities when you’re chipping wood.

For example, disc chippers aren’t as efficient as drum chippers. They use more energy and take more power.

Disc chippers, on the other hand, tend to produce chips that are more uniform, particularly when fed with quality raw material. This makes them ideal for commercial tree care companies that have large volumes of wood to deal with.

However, the problem with disc chippers is that the quality isn’t always as high if you’re dealing with raw material that’s not the best quality. For example, if you start feeding smaller branches or tops, you’re going to find that the chips are not uniform in size.

Therefore, drum chippers reign supreme when it comes to dealing with smaller branches and twigs. While a professional logger or arborist might want a commercial-grade disc chipper for cleaning up large pieces of debris on the job, the average homeowner wanting to clean up storm debris for use as mulch in the garden will do just fine with a basic rotary drum chipper instead.

Drum chippers may be slightly safer than disc chippers, though again, this is always variable. Most new drum chippers are equipped with safety features such as reversible feed systems. This allows newer-style drum chippers to handle large diameter materials (up to 20 inches) without the operator having to worry about any kickback or accidental discharge of wood.

Another benefit of using drum chippers instead of disc chippers is that they are slightly easier to maintain. It’s easier to change the knives on drum chippers (although the knives can be quite heavy, especially on something like a larger 12-inch drum chipper machine).

Drum chippers tend to make faster work on straight wood, while they aren’t as efficient on crooked or contorted branches. Disc chippers tend to be more compact, while drum chippers are lighter in weight.

So other benefits of drum chippers include:

● They offer better rotational energy and can cut a much wider swath than disc chippers

● They are more compact and often made to be more durable (and stronger)

● They can be easier to find, especially if you are looking for a machine that is 12 inches or larger

Ultimately, deciding between a drum or disc chipper will again come down to your intended use for the machine and what kind of wood you plan on chipping.

| Drum Chippers | Disc Chippers | |

| Structural Differences | The drum is used as a feeding mechanism to pull wood into a set of knives and then discharge the chips | Wheels draw material from the hopper back toward the disk; knives of the wood chipper cut the material up into chips and then discard them by flanges |

| Avg. Material Size | Up to 24 inches | Up to 19 inches |

| Application (When to Use) | Great for straight wood or casual use | Best for crooked, contorted branches or for professional arborists with large amounts of debris |

| Biggest Benefits | More compact and durable easy to maintain | Knives are lighter and more efficient for larger jobs |

| Concerns to Note | Can cause kickback on crooked wood | Wood chips aren’t always a uniform size |

When you’re shopping for a drum chipper, you might be wondering why you should choose this kind of chipper over others.

There are several key advantages posed by drum chippers.

For one, these machines are able to cut and crush raw material much better than other types – at a rate of more than 95% more efficiency, in fact. They can handle a higher capacity of wood and are easy to operate.

Not only that, but drum chippers tend to be easy to maintain and are made out of the best materials.

In addition, most large drum chipper manufacturer companies will tell you that drum chippers produce better quality chips. Drum chippers produce wood chips that are more uniform in size, both in terms of their average length and thickness. They have larger fractions of accepted chips and smaller fractions of fines and pin chips. Overall, the quality is just better!

When you’re operating a drum chipper, it’s good to know exactly what you’re getting yourself into!

Forestry wood drum chippers spin quickly with the rate of speed determined by the size and capacity of your machine. Some spin at a maximum rate of 540 RPMs (revolutions per minute), while others can achieve up to 3000 RPMs.

In general, 540 is the standard PTO speed for a small drum wood chipper. That said, there are some modern drum chippers that are operated off the PTO shaft of a tractor that can spin faster (around 1000 RPMs). It’s uncommon to see the higher RPMs unless it’s a very expensive, advanced commercial machine.

How Do You Use an Industrial Wood Chipper?

Whether you’re just cleaning up a bit of debris after a storm or you work for a professional arborist company, it’s helpful to know how to use an industrial drum-style wood chipper.

An industrial wood chipper can be a bit more complicated than a basic one, but they operate more or less in the same fashion. The chipper should be placed on level ground.

A wood chipper has a series of knives that cuts the wood into small bits as you feed it into the hopper. Feed the limbs, butt-first, into the hopper, releasing the branches as the rollers grip them. Some drip chippers have a mechanical feed bar along with quick stop and reverse feed control as safety features.

When feeding a shorter limb, use a longer branch to feed it in. Inspect each branch before feeding it for stones or other items that could damage the knives.

Once you place a branch into the hopper, roller bars grip the limbs, grind them, and then wood chips are made in a horizontal chipper drum before being forced out of a discharge chute. You’ll need to sharpen the blades regularly, or the wood chips will start to look more like chunks than chips.

Always follow the manufacturer’s guidelines for safety and operation and wear heavy-duty gloves while you’re working. It’s a good idea to wear eye and ear protection, too, along with close-fitting clothes.

This is a gruesome question that may come to mind after watching films such as Fargo, in which Steve Buscemi’s character is horrifically fed through a wood chipper.

It’s a dark picture, and frankly, one that you probably won’t ever have to ask yourself! However, wood chippers can easily shred a body. Bones don’t fare well against the shearing and torsion forces of a wood chipper.

Hopefully, you’re not planning on murdering anyone with your wood chipper! And obviously, you should never put someone through your wood chipper (do we have to tell you that?). Yet, it’s important to understand the power of this machine in relation to the human body as it serves as an important reminder – you’ve got to be careful while operating it!

Again, always follow the manufacturer’s recommendations for safety and wear safety goggles, hearing protection, and clothes that won’t get caught in the machine. Wood chippers are useful tools – but they don’t discriminate between wood and people!

So there you have it! Everything you need to know about drum chippers to help you make an informed decision when you buy – or decide to start one up on the job.

There are all kinds of machines out there to choose from, so regardless of your budget, the type of job you’re trying to tackle, and your personal preferences, you should be able to find a drum chipper to suit your needs.